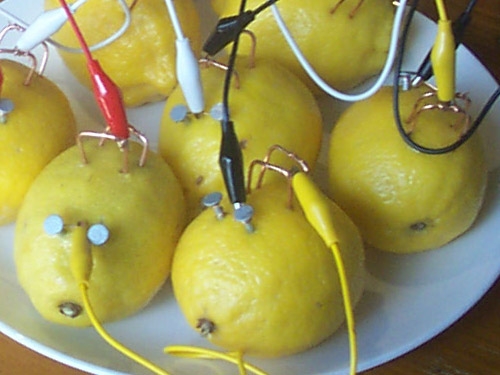

When you were a kid, you may have made a lemon battery for a school science project. These are very simple to make and involves inserting dissimilar metals into a lemon. Typical materials are copper staples and zinc plated nails. This combination usually gives you 0.7V and a few milliamps.

The chemical reaction that happens in a lemon battery is called “Galvanic corrosion” and it also happens when 2 dissimilar metals touch each other. For galvanic corrosion to occur, the following factors must be present:

- There must be two (electrochemically) dissimilar metals present

- There must be a conductive path between the two metals (eg they are touching)

- There must be a path for the charged ions to move between the metals (In the case of the lemon battery, this is the lemon juice)

To determine how similar or dissimilar the metals are, we use the anodic index which is shown in the table below.

| Gold, solid and plated, Gold-platinum alloy | 0.00 | |

| Rhodium plated on silver-plated copper | 0.05 | |

| Silver, solid or plated; monel metal. High nickel-copper alloys | 0.15 | |

| Nickel, solid or plated, titanium an s alloys, Monel | 0.30 | |

| Copper, solid or plated; low brasses or bronzes; silver solder; German silvery high copper-nickel alloys; nickel-chromium alloys | 0.35 | |

| Brass and bronzes | 0.40 | |

| High brasses and bronzes | 0.45 | |

| 18% chromium type corrosion-resistant steels | 0.50 | |

| Chromium plated; tin plated; 12% chromium type corrosion-resistant steels | 0.60 | |

| Tin-plate; tin-lead solder | 0.65 | |

| Lead, solid or plated; high lead alloys | 0.70 | |

| Aluminum, wrought alloys of the 2000 Series | 0.75 | |

| Iron, wrought, gray or malleable, plain carbon and low alloy steels | 0.85 | |

| Aluminum, wrought alloys other than 2000 Series aluminum, cast alloys of the silicon type | 0.90 | |

| Aluminum, cast alloys other than silicon type, cadmium, plated and chromate | 0.95 | |

| Hot-dip-zinc plate; galvanized steel | 1.20 | |

| Zinc, wrought; zinc-base die-casting alloys; zinc plated | 1.25 | |

| Magnesium & magnesium-base alloys, cast or wrought | 1.75 | |

| Beryllium | 1.85 | |

The rules of thumb are

- For temperature and humidity controlled environments, a 0.50V difference in anodic index can sometimes be tolerated

- For regular environments such as a warehouse, an anodic difference of 0.25V can usually be tolerated

- For harsh humid and salty environments it is best to limit the anodic difference to 0.15V

When we select mounting hardware for sale, we aim for an anodic index of 0.30. In the coming months you will find more and more of our hardware products nickle plated.